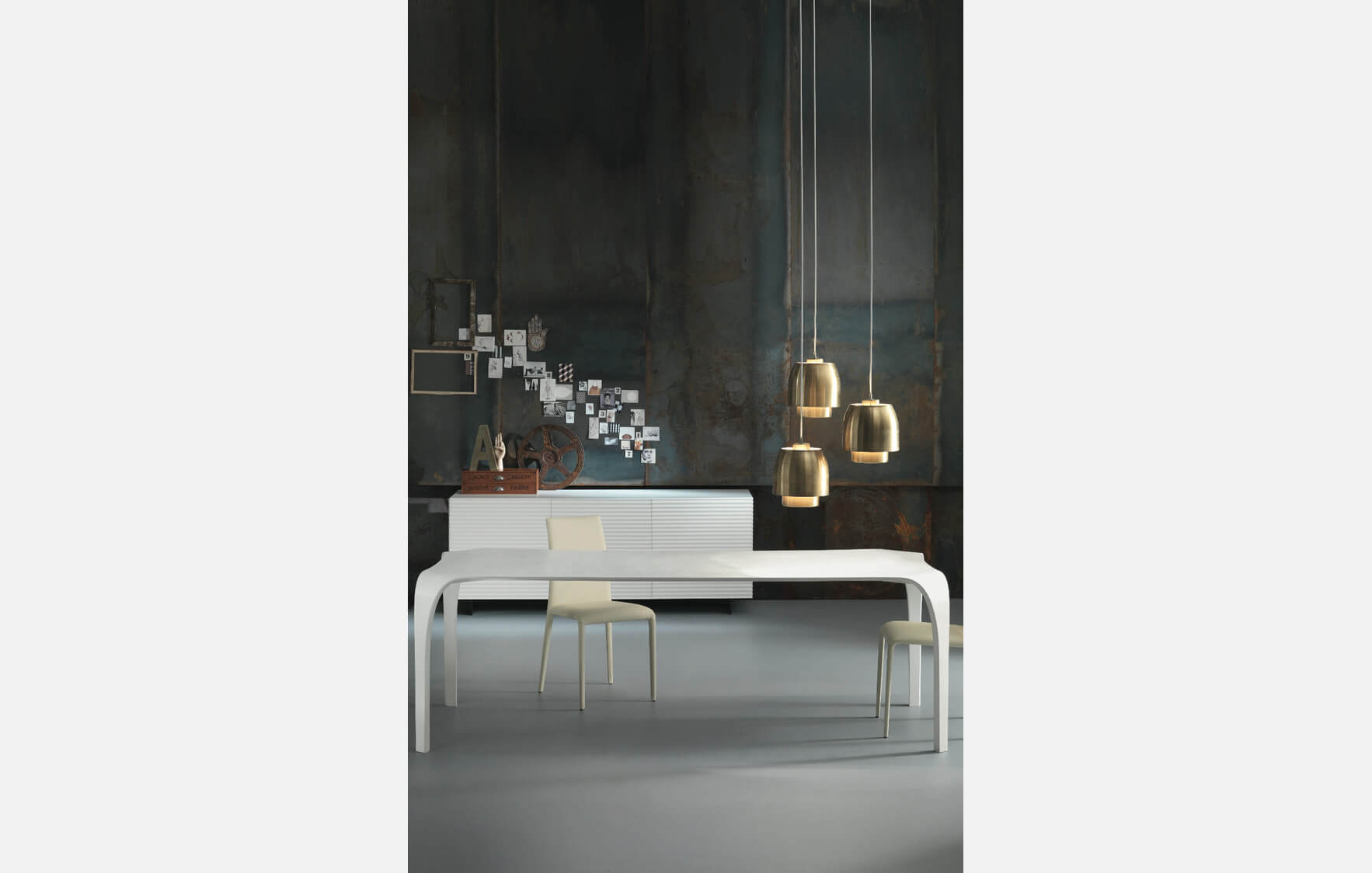

Tecnoril ®

100% Solid surface acrylic material , characterized by a high degree of whiteness and the ability to maintain colour stability over time, without yellowing. The natural, soft and warm surface conveys a pleasant feeling to the touch. Thanks to the intrinsic characteristics of the material and production process,Tecnoril® has great elasticity which translates into a remarkable resistance to impacts and thermal shock.

It gives a warm and pleasant tactile sensation similar to natural surfaces

The cold curing process enables the creation of flowing shapes and completely free of joints.

The exclusive Omnitech production technologies ensure total design freedom.

The surface can be cleaned with a soft cloth and water, and is suitable for contact with food.

The colour remains unaltered by light, and is highly resistant to stains, scratches and mould.

Damage or cut marks can be removed or repaired easily.

Can be cut, drilled, milled, planed or inlaid with normal wooden tools.

Does not release vapours, non-toxic if burned, and can be disposed of with household waste.

Finishes and textures

Finish: {{ valoreFinitura(nome_finitura) }}

Color: {{ fin.colore }}

HEX: {{ fin.hex }}

Technical features

|

Properties |

Test |

Typical Results |

Unit of measure |

|

Density |

DIN ISO 1183 |

1.76 ± 0.02 |

g/cm3 |

|

Flexural modulus |

EN ISO 178:2010 |

9060 ± 260 |

MPa |

|

Flexural strength |

EN ISO 178:2010 |

64.1 ± 1.6 |

MPa |

|

Shock resistance (Charpy) |

EN ISO 179-1:2010 |

4.1 ± 0.6 |

kJ/m2 |

|

Impact resistance (sphere) |

EN ISO 19712-2:2013 |

175 ± 10 |

cm |

|

Hardness (Barcol) |

UNI EN 4278 |

58 ± 3 |

HBa |

|

Resistance to bacteria and fungi |

nhibits the growth of bacteria and fungi |

No. of colonies |

|

|

Contact with foodstuffs (Overall migration) |

UNI EN 1186:2003 |

Σ<1.5 (Suitable, non-toxic) |

mg/dm2 |

|

Thermal expansion coefficient |

TMA ASTM 831:2012 |

Σ 0.030 |

mm/m/°C |

|

Degree of Whiteness |

>96 |

L (CIE-L,a,b) |

|

|

Stability to light (Xenon) |

UNI-EN ISO 4892-2:2013 |

5 |

Scale 1÷5 |

|

Resistance to heat and humidity cycles (60 cycles) |

PTP 45:1995 |

No defects |

— |

|

Resistance to temperature changes |

EN 14688:2018 EN 13310:2015 |

1000 |

cycles |

|

EN 14527:2019 |

100 |

cycles |

|

|

EN 14516:2019 |

100 |

cycles |

|

|

Stain resistance |

EN 14688:2018 EN 13310:2015 EN 14527:2018 EN 14516:2019 |

No defects |

— |

|

Fire resistant |

FTP Code MSC (61) 67:1988 |

Pass |

— |

|

Non-slip properties |

DIN 51097:1992 |

Class A |

Class A÷C |

|

Resistance to dry heat |

EN 13310:2015 |

No defects |

— |

|

Scratch resistance |

EN 14688:2018 EN 13310:2015 |

41 ± 2 |

μm |

|

Abrasion resistance |

EN 14688:2018 EN 13310:2015 |

460 ± 10 |

mg |

|

Conformity of CE marking |

Obtained |

||

|

CSA certification (Usa e Canada) |

Obtained |

||

Use and maintenance

…visualizza per informazioni…